- Part Detail

- CLICK TO VIEW

TRIUMPH PLATES - Browse Original Triumph Catalogue Plates

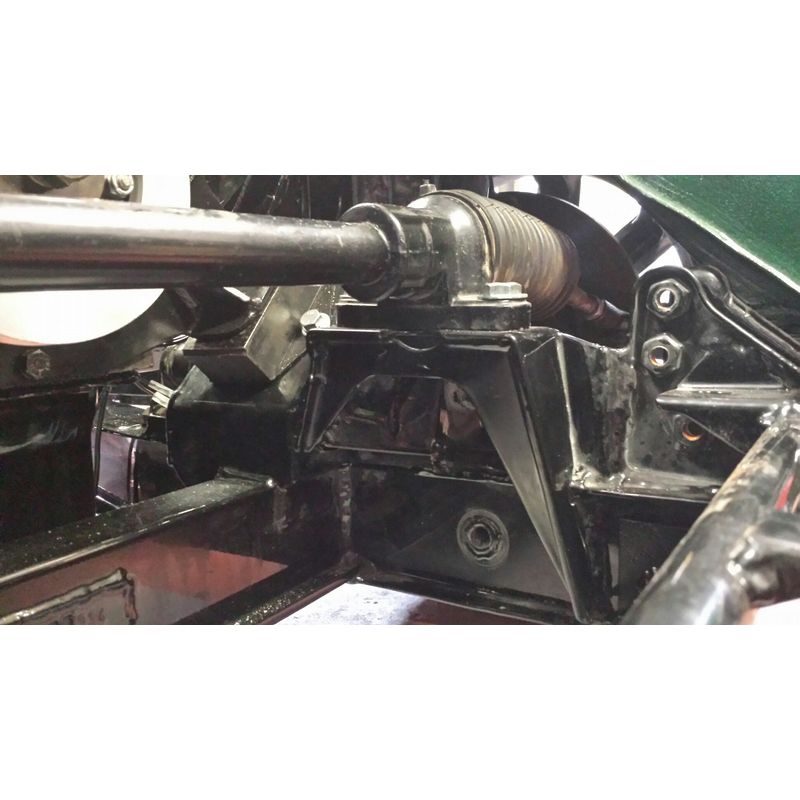

STEERING RACK CONVERSION TR2-3B LHD

NOT AVAILABLE This part is no longer available

This ingenious steering rack conversion developed by Revington TR fits Left Hand Drive TR's 2, 3, 3A, 3B and Italia, giving lighter steering, added safety and improved steering geometry. It incorporates a quick rack giving 2.15 turns lock to lock. This kit, developed in conjunction with our famous suspension kits, provides light steering and removes inherent bump steer.

Also due to a change in the steering arms, supplied with the kit, the new system provides toe-out on turns rather that toe in, which the original system exhibits. This ensures the car 'turns in' to corners rather than ploughing straight on.The basic rack is made especially for this kit and incorporates a rack bar of the correct length to ensure the steering behaves correctly. 2.15 turns of the steering wheel are required lock to lock which provides very quick steering. Owners contemplating fitting this kit to cars with the standard worm and peg steering system will be aware of how incredibly heavy the steering is even with the original 17 steering wheel fitted. This is due to a combination of the inherent stiffness in a worm and peg system (compared to a steering rack) and the standard lock to lock figure of 2.25 turns. Our quick rack kit benefits from the inherent lightness of a steering rack whist ensuring the lock to lock turns of the steering wheel satisfies the requirements of competition minded customers.

Standard kits RTR3202LK and RTR3202RK have a figure of 2.9 turns lock to lock and these kits should be considered by customers whose priority is very light steering.

Safety at Revington TR is a very high priority. The steering rack used in our kit has been chosen carefully for a number of reasons. One particular feature is the angle at which the pinion exits the steering rack ensuring the lower universal joint of the connecting shaft is always operating through a significant angle. This will minimise the likelihood of the steering shaft being projected directly rewards into the chest of the driver in a head on collision as the shaft will tend to deform sideways.

Kits RTR3202L-1K and RTR3202R-1K are supplied with newly manufactured steering arms to a modified design which corrects Ackerman angle errors inherent in the standard design. Only our kit incorporates this modification and is therefore unique in respect of this steering geometry modification.

TR2-3 owners with non-split columns, when installing this kit will need an upper column of the TR3A, TR3B split column type. If you do not have one, we can provide an inner and outer set RTR3315K. In addition it is necessary to utilize some of the TR3A column support parts, bolted to the bulkhead. To make life easier, we offer these as a kit RTR3406LK and RTR3406RK for either left or right hand drive. See below.

It is essential when fitting a steering rack kit that the rack bar sits in the same position as the original centre tie rod assembly. Our kit comes with brackets that have been carefully designed to fit in exactly the correct position on the chassis to ensure this is so. The brackets are firmly welded to the chassis to ensure there can be no movement of the steering rack with respect to the chassis.

When the steering rack is in the correct position, as the steering rack outer tube is much bulkier than the original centre tie rod assembly, the space occupied by the steering rack wants to be shared by the fan extension sticking out of the front of the engine. This must be removed and replaced with a short bolt kit RTR1027K and an electric fan kit, typically RTR1483A, will need to be fitted too.

In addition some new switches will be needed for the indicators and the horn. We supply a range of these, which can be found in section 8 of our downloadable catalogue and on our website in the 'Electrical Systems' section.

There is no technical way that the steering head containing the indicators and horn can be retained in working condition with any steering rack conversion. The head is held stationary by a long tube called a stator tube that goes right through the hollow steering column and is attached at the very forward end of the steering box by an olive seal and gland nut. It is this tube that carries the wires that operate the indicators and horn. The tube is called a stator tube because it stays stationary when the steering wheel and the column are turned around the outside of it.

As a steering rack has no facility to accommodate such a tube and there are two universal joints in the way, there is no way the stator tube can be refitted and there is therefore no way of holding the steering head stationary whist the steering wheel is turned through over two complete turns from lock to lock. It is therefore necessary to use the alternative horn and indicator switch options we offer to reinstate these functions.

As ever when there are several kits that appear to do the same job on the market, the characteristics of the kit should be examined very carefully before a choice is made.

Some kits on the market increase the turning circle of the car from 32 feet to 38 feet, making the car as difficult to manoeuvre as a large saloon car!

Some ill designed kits use too short a rack so that the rack comes to a stop before the steering stops are touched thus increasing the turning circle.

Our kit includes a rack with more movement than the steering requires so the factory fitted steering stops fitted to the vertical links are the items that set the turning circle. It follows therefore that the turning circle of a TR2-3B fitted with our steering rack conversion will be identical to original.

We often hear customers complaining about conversions bought elsewhere, typical comments include: The lock is restricted to less than two thirds of the original; the bump steer is quite noticeable. A major issue though with bolt on kits is that the bolted on arms apply huge force to the original steering box and idler chassis mounts. We at Revington TR have encountered these ripped off the chassis with this kind of kit fitted in the past. In some cases the fitters have had to saw bits off the rack to get it to fit too!

Steering rack kits RTR3202L-1K and RTR3202R-1K do not require the late TR4 upper wishbones or lateTR4 trunnions to be fitted at the same time but if the later 3 degrees of caster, which helps with self-centreing, is required, then these parts can be supplied separately. If the change to 3 degrees of castor is being made it would be a good time to introduce our upper fulcrum kit RTR3112K too.

If you have an adjustable steering wheel arrangement on a 'long' column you will not be able to use an adjustable wheel as the only 'short' upper column available is the fixed wheel type. There a very few adjustable steering wheel 'short' upper columns left in the world but if you have one of these and are intent on reusing it be aware that we have had one report of this in 20 years and may hundreds of rack kits sold that the wheel may end up slighter nearer to the driver (approximately 20mm in the case of the one report). We have not encountered this in our workshops so cannot verify this and of course the installation will vary from car to car. If the wheel position is unacceptable there are a couple of options.

Initial inspection and fitting

Please do be aware that the steering will seem stiff to start with, this should not be a surprise as the steering rack is brand new and will certainly appear stiff compared with the previous steering system which is likely to have covered many tens of thousands of miles and is being replaces because the old system was worn out and probably sloppy. Customer experience tells us that the steering will ease up after 100 miles or so and that when two to three hundred miles have been covered the rack will seem to have bedded in nicely.